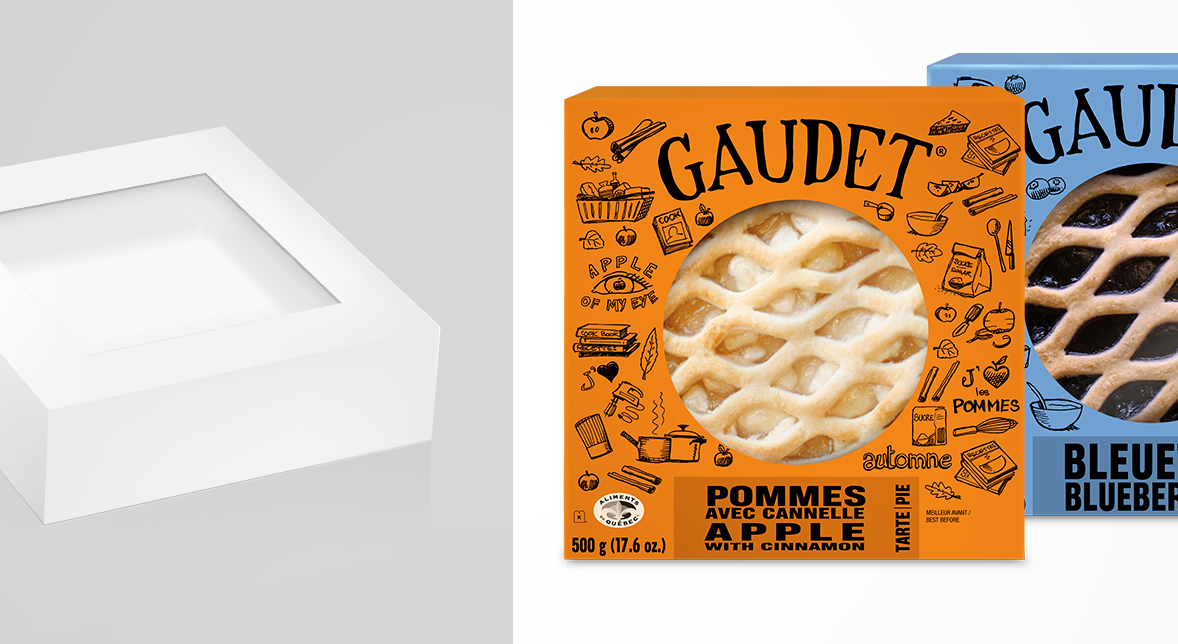

Often referred to as cellophane window patching or as windowing, this feature has become an increasingly important application in consumer packaging. It allows designers to add a whole new dimension to packaging and gives it an edge over its competition. A window on packaging can even trigger your customer’s curiosity! Adding rigid or flexible windows not only adds distinction to your package, it also provides visual appeal to your product, allowing consumers to instantly view and engage with your product, making it that much more appealing to your customers.

Cellophane window patching is commonly used in industries such as Food and Beverage, Cosmetics, Pharmaceuticals and even Retail. Have you ever noticed that most pie boxes have a small window through which you can see a decadent pie? What about cosmetics and electronics? Think about your facial cream box. Some cosmetics feature a cellophane window through that showcases their luxurious cream jar.

Rigid vs Flexible Windows

There are two options for cellophane windows: rigid widow and flexible window. The flexible window is a more cost-effective solution for windowing your product packaging. It’s usually made of a polyester film and it can be recyclable. It is ideal for packaging with curved structures due to its flexibility.

This type of window is used in food-contact packaging as it is approved in North America by some of the highest food-contact standards. The team of experts at Netpak are well-versed in regulations imposed by Health Canada and the FDA. Our food industry certifications, including BRCÒ, prove our ability and commitment to these high standards. Read more about our food industry approved certifications here.

While a flexible window may be more cost-efficient, a rigid window, commonly made of APET (a type of plastic resin), will provide a more luxurious appearance to your packaging and offers possibilities for unique designs. This type of film is commonly seen in cosmetics and pharmaceuticals or in packaging with large windows. Rigid windows provide crystal clarity and an effective way of displaying your product.

How is Window Patching applied?

Window patching is applied with a window-patching machine at the finishing stages of the production process. Often, window application is incorporated into the gluing process to provide faster turnaround times and lower costs. Netpak’s state-of-the-art technology allows continuously provide the fastest production times and avoid delays, while being cost-effective throughout the process. Better technology allows us to provide you with better packaging design options and improved visibility for your product with cellophane window patching. Learn more about Netpak’s state-of-the-art technology here.

Netpak: Printed Folding Carton Experts. Contact us today for a quote: sales@netpak.com | CANADA – USA 1-866-399-8544